|

Effect

Of Barium Sulphate As A Filler In Thermoplastic Polymer

For Medical Applications

Barium Sulfate as a filler

for composite preparation

Barium sulfate (BaSO4) is a

radiopaque material and filler used with medical-grade

polymers. Its specific gravity is 4.5. It is generally

used at loadings of 20 to 40% by weight. While a 20%

barium sulfate compound is typical for general-purpose

medical device applications, with striped tubing, for

example, a 40% compound is standard. As the barium content

increases, compounds begin to show losses of the base

polymer’s tensile strength and other mechanical

properties. It is therefore best to formulate radio

pacifiers at the minimum level for each application and

excessive use of these fillers is not recommended.

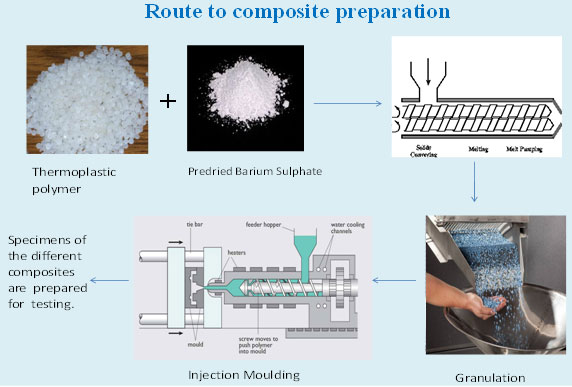

Method of composite

preparation

The barium sulfate is predried

before compounding. Thermoplastic polymers/BaSo4

composites are prepared using twin screw extruders with

increasing wt% loadings of barium sulphate. The material

coming through die is granulated after cooling through a

cooling bath. The granules are injection molded for

specimen preparation and testing. After testing the

results are studied and compared to decide application

areas. Once the required results are obtained the granules

of composites can be moulded or extruded to form end

products.

X-ray image of different

loadings with increasing wt% of Barium sulphate in

thermoplastic polymer Applications

|

|

|

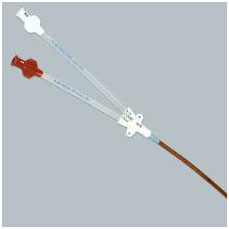

Dj stent (Used to bypass

kidney stone, temporarily after lithotripsy) |

Intravenous catheter (Used

to give fluids, drugs and for taking frequent blood

samples |

|

|

|

Endotracheal tube (Used to

ventilate, comatose or seriously ill patient) |

Drainage tubes (Used to

drain body fluids after surgery or in some diseases) |

|

|

|

Ryle’s tube (Used to give

drugs or food directly to the stomach) |

|

Medical devices used for

diagnostic and other interventional procedures require the

device to be clearly visible under X-ray. Radiopacity is

highly required in medical applications in use of devices

such as catheters, tubing’s, swabs, wires, body implants

and dental products. This is because these devices are

inserted inside the human body and need to be tracked

properly while its insertion and removal. Toys can be made

radiopaque so that if they are accidently swallowed by

children they can be quickly detected in X-rays.

References

-

Plastics in Medical Devices-

Properties Requirements and Applications by Vinny Sastri.

-

Robert A Baker and J.M.Huber,

“An over View Of The Hidden Minerals Of Polymer

Applications”, Polymers, Laminations and Coatings

Conference, 1997, 17-28.

-

Additives for Plastics

Handbook by John Murphy.

-

Functional Fillers for

Plastics, Edited by Marino Xanthos, Second Edition, Wiley

VCH.

-

Mallick P.K, Fiber-Reinforced

Composites Materials-Manufacturing and Design, 3rd Edn,

Boca Raton Publishing, 1993.

-

Quiyun Peng,” Radiopaque

Medical Devices Containing Bismuth Oxychloride” EMD

Chemicals Inc., An affiliate of Merck KGaA, Darmstadt,

Germany, Hawthrone, New York 10532.

-

Guangyu Lu et. Al.,” Rheology

And Processing of BaSo4-filled Medical Grade Thermoplastic

Polyurethane”, Polymer Engineering & Science, Oct.

2004,Vol.44,No.10, 1941-1948.

-

www.lubrizol.com

-

www.fostercomp.com

Page

1 :

2 :

3 :

4 :

5 :

6 :

7 |