|

E-beam

Sterilization : A Unique Opportunity For Indian Medical

Device Industry

V C Petwal

Radiation Processing In-charge, ARPF & Head,

Radiation Processing Lab, Department of Atomic

Energy, Govt. of India

Raja Ramanna Centre for Advanced Technology,

Indore, Madhya Pradesh - 452 012

vikash@rrcat.gov.in |

Mr V C

Petwal , Head , Radiation Processing Lab, Raja

Ramanna Centre For Advanced Technology (RRCAT

),Department Of Atomic Energy , Government Of

India located in Indore. RRCAT is working in

non-nuclear frontline research in the area of

accelerator and laser technologies. The facility

is designed, developed, commissioned and operated

by RRCAT under the “AtmaNirbhar Bharat Abhiyan” of

government India and providing radiation services

for medical devices sterilization ( e-beam

sterilization ) . The facility is licensed by

Atomic Energy Regulatory Board (AERB), Food and

Drugs Administration (FDA) MP state and has ISO

9001:2015 and ISO 13485:2016 certification for

providing electron beam processing service for

sterilization of medical devices as per the

requirements of ISO 11137.

In a

free-wheeling interview to “Medical Plastics Data

Service", apart from introducing the first e-beam

sterilization facility in the country , the

process of sterilization, Medical Devices that can

be sterilized by this technique, its comparative

advantages as well as how the Indian Medical

Device Industry can take benefit from this

facility.

Raja

Ramanna Centre For Advanced Technology (RRCAT) has

set-up an electron beam sterilization facility at

Indore. Can you please briefly share over view on

this facility? |

Raja Ramanna Centre

for Advanced Technology (RRCAT) is a Premier R&D

Institute of Department of Atomic Energy, Government

of India. RRCAT is working in non-nuclear frontline

research in the area of accelerator and laser

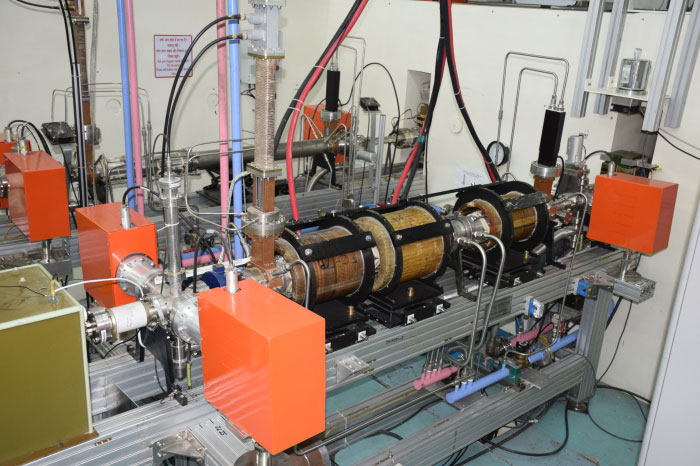

technologies. RRCAT has setup an in-house developed 10

MeV electron linear accelerator (Linac) technology

based radiation processing facility at Indore, Madhya

Pradesh. The facility is designed, developed,

commissioned and operated by RRCAT under the

“AtmaNirbhar Bharat Abhiyan” of government India and

providing radiation services for medical devices

sterilization. The facility is licensed by Atomic

Energy Regulatory Board (AERB), Food and Drugs

Administration (FDA) MP state and has ISO 9001:2015

and ISO 13485:2016 certification for providing

electron beam processing service for sterilization of

medical devices as per the requirements of ISO 11137.

With these credential and approvals, this is the first

e-beam facility in the country providing commercial

radiation sterilization service to the regulated

medical devices.

RRCAT Linac based

e-beam sterilization facility at Indore

Different medical devices

sterilized with e-beam

Apart from commercial

sterilization of medical devices, the e-beam facility

is being used by many institutes, universities and

industries across the country for variety of research

applications such as sterilization of pharmaceutical

API, irradiation of seeds for developing new crop

varieties, modification of semiconductor device

properties, colour modification of gem stones etc.

We understand you have already started offering this

facility to the Industry. Can you please explain how

is this facility being offered to Indian Medical

Device Industry?

Yes,

Being the first e-beam

facility in the country, various protocols/ process/

procedures are designed & developed to fulfil the

requirement of Schedule IV & V of MDR-2017 and ISO

13485. The facility is critically audited by AERB,

FDA, CDSCO notified bodies and after taking regulatory

approvals & ISO certifications, RRCAT started offering

radiation sterilization services to Risk Class-A and

Risk Class-B medical devices on commercial basis.

As the Government of

India is celebrating the “Azadi ka Amrit Mahotsav”, to

commemorate 75 years of progressive India and it’s

achievements, DAE has decided to celebrate it by

providing the e-beam sterilization service with

indigenous Linac technology, at concessional rates.

Medical device manufacturers from all around the

country are welcome to take the advantage of the novel

e-beam technology to sterilize their devices. Detail

information on the procedure to be followed for

availing sterilization service is provided on the

link:

https://www.rrcat.gov.in/organization/cat/incubation/ebrpf.html.

In short, the facility

have all the technical capabilities and control on

process to provide e-beam sterilization services to

Medical Device Industry, in conformance with

international standard.

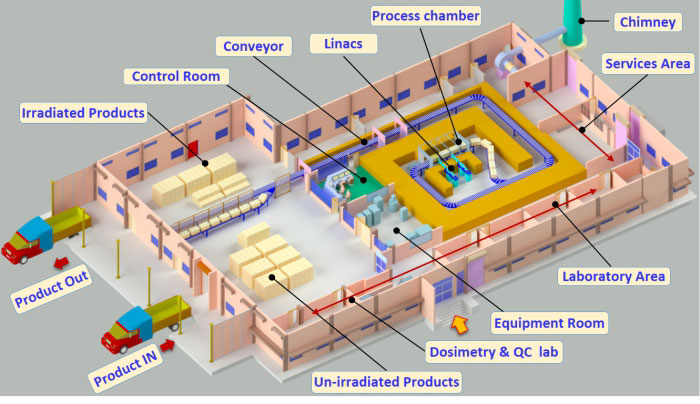

Layout of electron beam

radiation processing facility

Currently the Indian Industry is using either ETO

Sterilization or Gamma Ray Sterilization process. Can

please explain advantages of using e-beam

sterilization.

Sterilization by EtO

requires long exposure time (typically 5-6 days),

leaves chemical residue on devices and requires

expensive breathable packaging for medical devices.

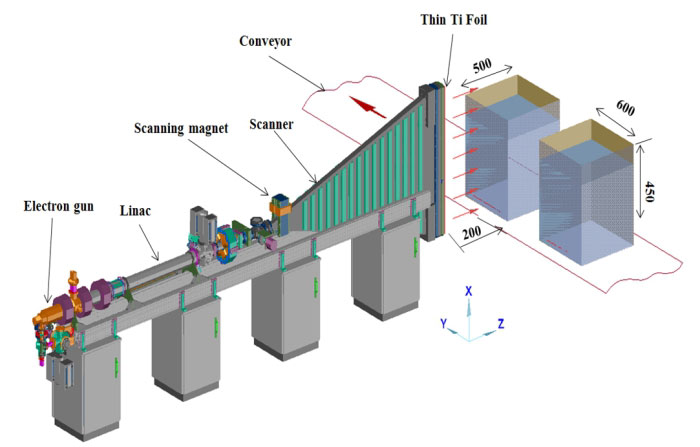

Ionizing radiation is an attractive method for

terminal sterilization of medical devices. Electron

beam sterilization is equivalent to sterilization

performed with Co-60 Gamma radiation. For example

Gamma irradiation, e-beam doesn’t leave any residue

and requires no post processing quarantine time. The

processing time in electron beam is faster and based

on ON/OFF technology. Electron beam is eco-friendly,

and inherently safe and secure technology, due to

which its application is increasing at a rapid rate.

The medical devices are sterilized in their final

packaging using the penetrating power of electron

beams (without the need for opening packing).

Are there any limitation of using e-beam sterilization

particularly with respect to penetration or any other

output?

Typical scenario of

radiation processing using electron beam

|