|

Medical Polymers :

Emerging Trends & Opportunities

Medical Tubings : Common Applications

|

Sr. |

Materials |

Common

Applications |

|

1 |

Polyvinyl Chloride

PVC |

Containers used

for blood and blood components for urine or for

ostomy products and tubing used for blood taking

and blood giving sets, catheters, heart-lung

bypass sets, haemodialysis set etc. |

|

2 |

Polytetrafluoroethylene, PTFE |

Catheter liner,

Electrical Insulation, Fluid transfer,

Telecommunication |

|

3 |

Fluorinated

Ethylene |

IV catheter,

Regional Anesthesia, Vascular access |

|

4 |

Ethylene

Tetrafluoro ethylene, ETFE |

Fluid transfer, IV

catheter, Electrical insulation |

|

5 |

Perfluoroalkoxy,

PFA |

Fluid transfer, In

Vitro diagnostics |

|

6 |

NYLON, 6, 11, 12 |

Angiography,

Choloecstectomy, Epidural catheter, Laparoscopic

instruments, Radiology |

|

7 |

Polyether Block

Amide, PEBA |

Angiography,

Cholangeography, Epidural Catheter, Radiology |

|

8 |

Polycarbonate PC |

Laparoscopic

instruments, IV therapy, Laparoscopic cannulae,

Tube packaging, Microtubes |

|

9 |

High Density

Polyethylene LDPE |

Embolectomy,

Guidewire dispensers, Introducers, Protective

tubes, Thrombectomy, Sheaths and dilators for

introducers, Coextruded perfusion tubing,

Aspirator tips |

|

10 |

Low Density

Polyethylene LDPE |

Embolectomy,

Guidewire dispensers, Introducers, Protective

tubes, Throbectomy |

|

11 |

Polyurethane PUR

(Aliphatic) |

Angiography,

Cardiac catheters, Central Venous catheters,

Dialysis, Epidural catheters, IV catheters,

Epidural probes, Catheters, Highpressure lines |

|

12 |

Polyurethane PUR

(Aromatic) |

Angiography,

Cardiac catheters, Central Venous catheters,

Dialysis, Epidural catheters, IV catheters |

|

13 |

Polypropylene PP |

Guidewire

dispenser tubes and Protective tubes |

|

14 |

Ethylene Vinyl

Acetate EVA |

Endotracheal,

Embolectomy, IV therapy, Suction catheter |

|

15 |

ACETAL |

Laparoscopy,

Guiding catheter |

About Catheter Tubing :

Number of variables affect the performance of a

finished catheter the most paramount being the

properties of the raw material and the extrusion

process. Careful consideration of the extrusion

process is essential to ensure consistency and

repeatability.

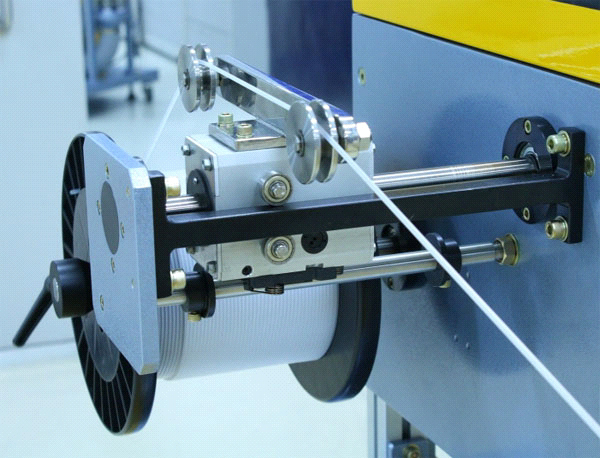

Single- or dual-screw extrusion is used to manufacture

catheter tubing.

During the extrusion process, air at a specific

pressure is used to obtain the intended tubing shape.

A heat-transfer process begins as the polymer exits

the die. Air is used as the initial cooling medium,

followed by water in a cooling bath. A belt or wheel

hauloff (puller) pulls the tube from the die and

through the cooling bath at a controlled speed.

Because of the complexity of catheter tube

manufacturing, several parameters associated with the

extrusion process may affect the properties of the

finished product.

1 These parameters include:

Temperature profile.

Initial method of drying the polymer granules.

Temperature of the cooling bath.

Tubing dimensions.

Screw geometry.

Rotational speed of the screw.

The distance between the die head and the cooling

bath.

Polymer choice can also affect the finished

product's properties.

Critical Applications - Medical Tubing

Configurations - Material & Process Requirements For

High-Quality Extruded Tubing - Economics Of Extrusion

Enhancing performance and design

Following are the various features incorporated in the

catheter tubings to enhance performance depending on

the applications :

Braid/coil reinforcement for strength, rigidity and

torque control along the length of the catheter to

balance the need for flexibility and kink resistance

to navigate tortuous pathways.

Use of hydrophilic coatings delivers high lubricity

to achieve low insertion force or a reduction in

friction for a specific delivery application.

Soft tip and multi-durometer segments along the

length of the catheter provide atraumatic entry and

maneuverability.

Radiopaque contrast at the tip and key segments

offer better visibility for the physician to visualize

accurate anatomical placement.

Steerability and deflection help attain optimal

navigation.

Methods To Assess Tubing Properties :

Briefly. methods used to measure the effects of

extrusion parameters on the final product and for

comparison with the original polymer characteristics

include : optical microscopy, tensile testing,

rheometry testing, IR spectrophotometry, and enthalpy

differential analysis.

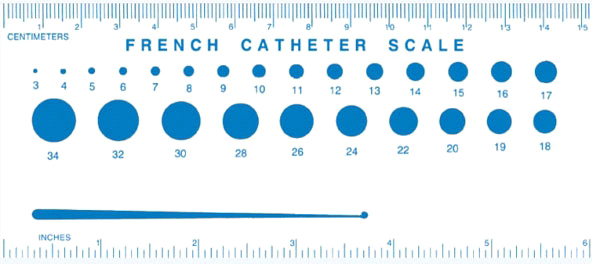

Measuring Catheter Tubing Sizes

Problems can arise when the customer and catheter or

tubing supplier are not using the same scale when

discussing catheter tubing sizes.

French scale and gauge scale are the measures used to

refer to the diameter of catheters and tubing. While

each have certain advantages, misinterpreting these

standards can lead to confusion. OD and ID are

abbreviations for outer dia meter and inner diameter,

respectively, and are generally measured in inches or

millimeters.

The catheter sizing classification most commonly used

in the medical industry is the French (Fr) scale, also

known as the Charriθres system. The French scale is

an easy method to use to describe the basic size of a

catheter, because it specifies the most obvious

component, the outer diameter. The French size = 3

times the diameter in millimeters. The disadvantage of

the French scale is that it does not specify the inner

diameter of the catheter or tubing. Thus, the French

sizing used alone, is not specific enough to

adequately describe small catheters, where internal

diameter is critical. This scale is much more useful

to specify larger catheter sizes.

A second method of sizing catheters is the gauge

measurement. Gauge is a descending scale, opposite the

French scale of measurement which ascends with

corresponding size. The higher the gauge size the

smaller the tubing.

Another less common method for sizing catheter tubing

is the PE scale. It is specific to polyethylene and

is an ascending scale used by some manufacturers to

represent the OD and ID of the tubing, similar to

French sizing.

The most definitive method to describe a catheters

dimension is simply to state the exact measurements of

both the outer and inner diameters. While it may seem

a little more difficult to communicate, this method

will actually give all the details necessary to the

researcher or catheter manufacturer to properly size

your specific catheter and catheter connections.

The Economics Of Extrusion

Important elements of Expenses in the medical tubing

extrusions are : Materials, Equipment, Direct Labour,

Others (includes : Power, Packaging, Insurance etc)

In most of the cases , the largest cost is the

material.

Extrusion is usually a 24-hour continuous operation.

Frequent starts and stops greatly increase production

costs.. |