|

Drug

Delivery Device Using Polymers With Improved Tribology

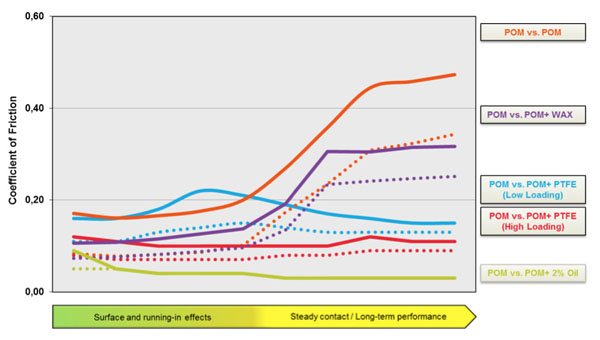

*First cycles

simulate running-in effects, mainly important in

single-use medical devices. Running-in effects reflect

breakaway forces, lubricant contamination, asperities

and injection molding effects on virgin surfaces. On

the other hand, multi-use injectors and inhalers focus

on long-term performance, which is analyzed during the

second part of the measurement, called “steady

contact”.

THE USE OF INTERNAL LUBRICATION

Internal lubrication of polymers is

achieved either during production via the use of

master batches in the injection molding process, or as

a ready-to-use compound directly from the raw material

supplier. It is difficult to match the extremely low

levels of friction achievable by surface film

lubrication. Regardless, when the right lubricant is

used for the combination of base polymers involved,

excellent results can be achieved. The type and form

of the lubricant is critical. Some lubricants have

excellent dispersion within the polymer (i.e. waxes)

and migrate to the surface of the polymer during

injection molding. Others form discrete pockets of

lubricant (i.e. PTFE) requiring a running-in phase to

get some initial surface wear to be exposed to optimum

lubrication potential. Figure 5 gives an overview of

the sliding performance of unmodified POM-on-unmodified

POM, resulting in the highest coefficients of friction

as well as versus POM with different tribological

modification (internal lubricants).

Figure 5: The influence of different internal

lubrication on coefficient of friction (CoF), dotted

lines: dynamic CoF, solid lines: static CoF

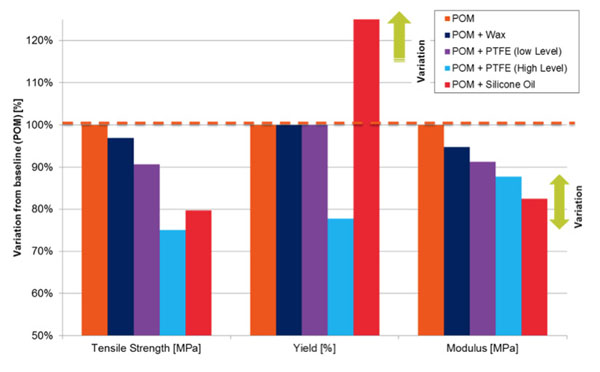

Some of the modifiers that improve

sliding performance in POM strongly influence the

mechanical properties of the material as depicted in

Figure 6. While the addition of silicone oil provides

excellent tribological performance, the oil can also

result in a

Figure 6: The influence of different internal

lubricants on mechanical properties |