|

Pipette tips –

Precision In High

Quantities

Innovative Mold

Technology in a Compact Cluster Design

Especially under the effect of a global pandemic,

identifying infected people at an early stage has

proven an effective measure for breaking the chains of

infection and stopping the spread of easily

transmissible diseases. Identifying these people

requires testing capacity on an in¬dustrial scale that

can test as many people as possible, with or with¬out

disease symptoms, in a short period of time. A small

but important plastic part in these testing systems is

the pipette tip, which is used to take liquid samples

and accurately transfer them into corresponding test

devices. Requirements for

pipette tip.

Pipette tips differ in their shape and

size, depending on the intended purpose. As a

sensitive part in the measurement system that is in

direct contact with the sample, and that can influence

the measurement, pipette tips need to meet high

standards:

-

exact dimensional accuracy to be able

to pick up the smallest amounts of liquid, just a few

microliters, and transfer them precisely

-

flawless concentricity for precise

positioning when using pipette robots

-

freedom from burrs in the tip area,

which can falsify the measurement result due to

surface effects, such as adhesion

-

purity to avoid contaminating the

sample

Pipette tips are a challenge for

industrial production because they are required in

large quantities with the highest quality. This

challenge is transferred to the tooling manufacturer,

which needs to ensure high-tech and reliable solutions

for the demanding component geometry with thin walls

and long flow paths.

Schöttli AG supplies pipette tip molds

in the 8-series cluster design, a hot runner system

with lateral gating for the efficient and reliable

manufacture of high-precision pipette tips, a system

which has been proven for over 30 years. Thanks to the

compatibility of the SCHÖTTLI 8-series cluster design

with standard pitch circle diameters, SCHÖTTLI molds

can be integrated into existing automation solutions

without being modified. Moreover, the SCHÖTTLI mold

concept offers maximum productivity and the highest

level of reliability. For maintenance work or

adjustment, the cores of individual clusters can be

removed from the clamped mold in the injection molding

machine (cleanroom production) and precisely set.

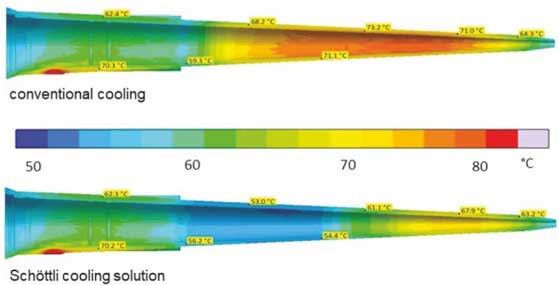

Fig. 1: Uniform heat dissipation thanks to

efficient cooling

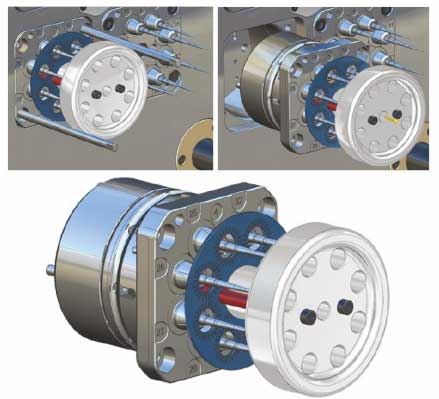

Fig. 2: Positioning of the pipette

cores

Cluster design - Adjustment and

maintenance

By accumulating production tolerances of different

components, and the true installed position within the

molding assembly, it cannot be ensured that the

pipette core is in the center of the cavity. There is

also the injection pressure during the filling phase,

which causes the core to deform and leading to

different shrinkage on the plastic part, thus reducing

the concentricity of the pipette tips. The innovative

SCHÖTTLI adjusting mechanism makes it possible to

easily set the concentricity in a precise manner

ensuring it is optimal. The cluster design offers

additional advantages such as, uniform water flow

through the smallest holes, as well as having the

ability to accurately adjust the pipette cores on the

workbench in an assembly-friendly manner without

removing the mold from the injection molding machine.

Core cooling at the highest level

Efficiently cooling the plastic molded part requires

innovative solutions in mold cooling to ensure the

fastest cycle times, and the highest product quality.

A good thermal balance reduces the physical component

distortion and is a crucial quality requirement when

it comes to the concentricity of the pipette tip.

Cooling the smallest diameters in the core tips and a

near-contour cooling of the mold inserts ensure a

homogeneous and efficient heat dissipation for maximum

performance.

Getting a handle on burr formation The thin walls and

diameters in the tip area require a reliable solution

to produce burr-free parts, with simultaneously

optimal cavity venting. High-precision and engineered

mold components, combined with the reliable SCHÖTTLI

hot runner system, ensure a stable manufacturing

process with the highest product quality. With the

innovative SCHÖTTLI solution, core bushings can be

directly and easily changed while the mold is

installed in an injection molding machine.

SCHÖTTLI as a partner for producing

pipette tips

SCHÖTTLI AG, a HUSKY Company, offers

safe and efficient solutions for complex applications

in the medical and pharmaceutical industry. With its

own pipette test mold, SCHÖTTLI offers the possibility

to perform material tests or implement special

customer designs. It does not matter how high the

requirements for the mold are – SCHÖTTLI molds offer

high part quality and permanent reliability.

www.schoettli.com

|

hiren.khatri@schoettli.com

Hiren Khatri - Key Account Manager Medical Molds SAARC. |