|

Polymer Ceramic

Hybrid Acetabular Liner: Bench to Bedside Translation

|

|

Dr. Bikramjit Basu

Professor at the Materials Research Center IISc,

Bangalore |

According to a published report of the

World Health Organization (WHO), about 190 million

adults suffer from osteoarthritis and related

disabilities worldwide. This is commensurate with the

fact that the number of revision surgeries has

increased at about the same rate as the number of

primary surgeries of joint replacement due to

prostheses failures. Currently, there are more than

100,000 cases every year of Total Hip Arthroplasty (THA)

procedures in India. The available articulating

joint-implants generally offer a trouble free life for

about 10-15 years, which is inadequate, considering

the increased lifespan for humans in many developing

nations. Therefore, a search for ideal prosthetic

materials together with treatment methods,

reconstructive solutions and surface designs is

currently being pursued in the field of orthopedic

biomaterials.

The global orthopedic market was

approximately 30% of the total implants market and the

market shares of segments in 2020. The growth rate of

the need for orthopedic implants is estimated to be

more than 25% per annum for the next five to six

years. The global hip replacement implant market is

expected to grow at a Compound Annual Growth Rate (CAGR)

of 3.0% during the forecast period 2017–2023 to an

aggregate of $7,150.0 million by 2023. The overall

trend therefore shows a steady, yet slow expected

market growth in the THR application domain. The THR

market is further sub-divided into three sectors:

total hip replacement, partial hip replacement and

revision and hip resurfacing. Although several hip

implant options are available commercially, these are

currently imported and there are no affordable

indigenous alternatives.

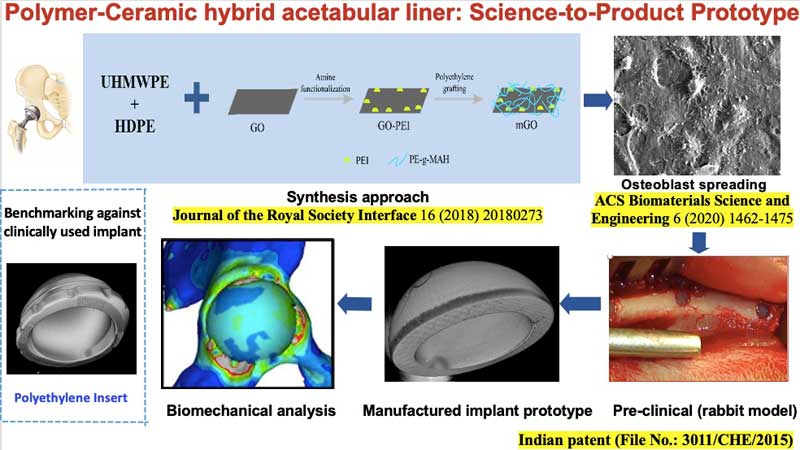

In a decade-long research program,

Prof. Bikramjit Basu’s research group at Indian

Institute of Science, Bangalore, made

important breakthroughs in developing

three different generations of polymer-ceramic hybrid

acetabular sockets, namely HDPE-HA-Al2O3 hybrid

composites, polyethylene grafted graphene oxide (GO)

reinforced high density polyethylene (HDPE) composites

and lately, a UHMWPE-HDPE blend with surface modified

GO reinforcement. For example, a new synthesis

approach was developed to chemically couple GO in

polymer blends, which resulted in high mechanical

strength (~65 MPa) and wear resistance properties with

acceptable biocompatibility. Research on this

technology has also been conducted at IIT Kanpur.

Gamma irradiation of the acetabular

liner was shown to help in improving wear resistance,

hardness and coefficient of friction, without

compromising on biocompatibility. Improved wettability

and surface polarity after gamma-ray sterilization

further supported cell adhesion and stability of

coefficient of friction. The resulting wear debris

were found to be non-toxic. Optimum implant design was

determined using Finite Element Analysis and

theoretical wear analysis, and was customized

according to the bone condition and body weight of the

patient. It was shown that implant stiffness could be

optimized to be close to the natural strain profile

within bone.

The scalability for manufacturing of

acetabular liners (44, 46 or 48 mm outer diameter with

8 mm wall thickness) with acceptable surface finish

has been established at the prototype level. The new

implant design was accomplished by biomechanical

analysis of principal stresses in periprosthetic bone

around the acetabular joint, and current efforts are

underway to adopt machine learning algorithms to

accelerate the implant design. The augmented bone

tissue regeneration around the variants of hybrid

composite were demonstrated in both cylindrical and

segmental defect models in femurs of experimental

rabbits for a period of up to 26 weeks. |

|

|

|

|

Advertisers'

Index

|

|

Accuprec Research Labs Pvt. Ltd., India |

|

Ambica Medicare Engineering, India |

|

Nu-Vu Conair Pvt. Ltd., India |

|

Celanese Corporation, India |

|

CLS Pvt.

Ltd., India |

|

Carclo Technical Plastics Pvt. Ltd.,

India |

|

Covstro India |

|

ET Elastomer Technik, Germany |

|

Eewa Engineering Co. Pvt. Ltd., India |

|

Ineos Styrolution India Ltd., India |

|

I-Kare Polyalloys Pvt. Ltd., India |

|

KLJ

Group, India |

|

Lubrizol Advanced Materials India Pvt.

Ltd. |

|

Lyondellbasell, India |

|

Mediscient Devices (OPC) Pvt. Ltd., India |

|

Milliken & Company, India |

|

Maider Medical Industry Equipment Ltd.China |

|

Mega Compound Co. Ltd., China |

|

Milacron India Pvt. Ltd., India |

|

GLR Laboratories

Pvt. Ltd., India |

|

HighRichja Precision Extrusion Machinery Co. Ltd., China |

|

PVC Colouring Compounding & Processing,

India |

|

Qosina,

USA |

|

Raumedic AG |

|

San

Printech Pvt. Ltd., India |

|

Schottli, Switzerland |

|

SMC Medical Manufacturing Pvt. Ltd.,

India |

|

Steri Techno Fab, India |

|

Tekni-Plex India Pvt. Ltd., India |

|

Twist Engineering Works,India |

|

Airways Surgical Pvt. Ltd., India |

|

Alpha Medicare and Devices Ltd., India |

|

Alpha Therapeutics Pvt. Ltd., India |

|

Angiplast Pvt. Ltd., India |

|

Beacon Plastics, India |

|

Delux Surgical, Inida |

|

Jain Rubbers Pvt. Ltd., India |

|

New

Vimko Plastics, India |

|

Operon Strategist, India |

|

R.R. Patel Gases (P) Ltd., India |

|

SEC Global Consulting & Initiative LLP,

India |

|

Surgi Pack India Pvt. Ltd. |

|

Vinit Performance Polymers Pvt. Ltd., India |

|

Amigo Surgi Care

Pvt. Ltd., India |

|

Apex Medical Devices, India |

|

Jimit Medico Surgicals Pvt. Ltd. |

|

Life-O-Line Technologist, India |

|

Mesco Surgical, India |

|

Morrisons

Lifecare Pvt. Ltd., India |

|

National Healthcare, India |

|

Pharmadocx, Inida |

|

S. Nath & Co., India |

|

Unikal Consultants, India |

|