|

Opportunities For New

Entrepreneurs In Medical Textiles -

A Sun Rise Industry And Role Of Centre Of Excellence SITRA

In Promotion Of Medical Textiles

4.Textile structure in Medical textiles

Medical textile products can be made from

each stage of textile manufacturing. Textiles structuring

is broadly divided into 4 categories : - fabric, yarn,

fabric and garments.

Product such as surgical cotton, wadding,

ear buds, etc., is produced directly from textile fibres.

Products such as sutures, heart valve stitching thread,

dental floss, dialysis membrane filaments produced gram

filament / yarn etc. In fabric structure there is further

classification in terms of woven (vascular graft, reusable

bed sheets & pillow covers), non woven (surgical gowns,

disposable bed sheets & pillow covers), knitted (vascular

graft, hernial mash, heart patch fabric), braded (Anterior

cruciate ligament sutures etc), (rotator cuff). All the

operational theatre garments come under stitched garment

products (surgical gowns, bed sheets, etc), products made

up of different textile structure (sanitary napkin/under

pad, fibers of non woven, wound dressing – fibers +

woven/non woven/knitted structure, etc.

5. Overall opportunities in medical

textiles

Opportunities lies in technical textile

machine manufacturing, specialised raw material

manufacturing, setting up laboratories to test these

materials /products, manpower training, etc.

-

Many medical textile products are imported

and not manufactured in India, so there is a huge

potential for manufacturing them in India. Many medical

textiles products are classified as medical devices. There

is no concrete data available for medical textiles, but

80% of medical devices are imported.

-

Though India is the second most populous

country, the penetration of medical textiles is very less

in India due to factors such as less awareness among

people, cost of products and non availability of many

products to common people. But now the usage of medical\

technical textiles is increasing due to the new generation

with a higher disposable income, more education, easy

access to media/internet.

-

Higher child birthrates - mother and

child.

-

Medical tourism - Cost of getting treated

is cheaper and faster compared to the developed countries.

-

More modern hospitals are coming up, so

growth of medical textiles is proportional by hiked with

growth of medical business.

-

Increased awareness for Medical insurance.

Medical insurance companies insist hospitals to maintain a

proper environment to reduce risk of HAI.

-

The shift in Indian culture to western

influence and globalisation has created / helped in

creating more awareness about usage of medical textiles in

day-to-day life such as wipes, sanitary napkins, diapers

to maintain cleanliness & hygiene environment.

-

Many medical textiles are used for

maintaining an hygienic environment. Young Indians are

interested in more comfort and cleanliness.

-

Availability of almost all basic raw

materials in India.

-

Mandating suggestions by GOI in different

ministries such as MoD, MoHFW, MoLE, MoR, MoHA.

-

Government initiatives by creating centres

of excellence in different fields of technical textiles.

Formation of Centre of excellence for medical textile at

SITRA has helped industry in many areas such as R&D,

standard formation, testing/characterisation etc.

-

Proactive approach of government towards

boosting TT sectors by different government scheme for

business community in terms of subsidies, special zones (Meditech

zone, Visakhapatnam), ATUF, TMTT, etc as well as promotion

of the TT scheme by every state government.

-

Government is planning to mandate a few

products as per BIS standards; this will help to eliminate

usage of substandard products (manufactured or imported).

-

Creating awareness such as distribution of

free napkins by many NGOs as well as government agencies

-

Cheap labour and abundance of manpower,

cheap power compared to many countries can help

manufacturing cheaper medical textile products.

-

Mandating purchase from MSMEs

-

Schemes such as Swachh Bharat Abhiyan,

Ayushman Bharat.

-

M/C manufacturing for medical textiles

such as Sanitary napkin making ,face mask making m/c etc

have potential to grow huge.

6. Sector wise opportunities in medical textiles

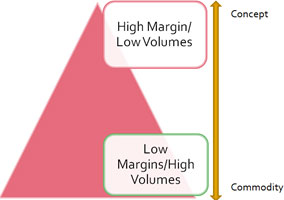

6.1 Implantable

Usually not many life saving products are manufactured in

India. India is almost fully dependant on imports.

Ultimately, very costly products are not affordable to an

average Indian. If invented and manufactured by Indian

companies, the cost may come down drastically. Lives of

many Indians can be saved. Though the demand is low and

the regulatory requirements are stringent, the profit

margins are high.

6.2 Non-implantable

These are the products that are used on the skin. Low

profit but high demand.

6.3 Extracorporeal devices

Same as Implantable life saving and again

very costly products dependent highly on imports. Though

the demand is low and the regulatory requirements are

stringent, the profit margins are high.

6.4 Hygiene textiles

Not much dependant on imports but still

MNCs of foreign origin have considerable stake compared to

the Indian manufacturers. Demand is high and investment

required is low.

6.5 Healthcare textiles

Not much dependant on imports but still

MNCs of foreign origin have considerable stake compared to

Indian manufacturers. Demand is high and investment

required is low.

7. Challenges for medical textile

business

-

Medical device products may require

license to produce or sell products in India (New medical

device rule is implemented recently).

-

And still classification of medical

textiles under different categories as medical devices

will take time.

-

Still many medical products are needed to

be classified as medical devices. It may have impact on

the small scale industry.

-

Lack of standards - So far, SITRA has

identified many medical textile products and have

developed standards for those.

-

Non availability of expertise for the

manufacture of specialised raw materials Kevlar, Nylon66,

Aramid, etc., and machinery manufacturing techniques in

India.

-

Lack of interest, awareness and confidence

among big industries to enter into the Medical Textile

business.

-

Scattered industry.

-

Lack of trained skilled manpower with

interdisciplinary knowledge.

-

Disposal of medical textile wastes.

-

Cheap import from neighbouring countries

such as Bangladesh, China due to reasons such as lack of

BIS standards.

|