|

Material

Selection For Injection Molded Medical Parts

|

Suresh V,

Sr. Manager Market Development, Covestro (India)

Private Limited |

Medical devices are often designed

with complex geometry to meet very high precision

hence injection molding the parts involves high

skills, precision molds and the material that

complements the both. Material selection is very

important for the development of a successful product.

Considerations such as appearance, colour and key

properties like mechanical strength and heat

resistance are vital.

Material selection is very

important for the development of a successful product.

To meet the in-use functional

requirements, considerations such as appearance,

colour and key properties like mechanical strength and

heat resistance are vital for medical applications.

However, there are additional considerations such as

chemical disinfectant compatibility, sterilization

requirements and regulatory fulfillment. |

The other factors that influence the selection of material

includes the ease of processing, local availability and

long term continuation of the

product and the commercial viability (cost of the

material). Medical devices are often designed with complex

geometry to meet very high precision hence injection

molding the part involves high skills, precision molds and

the material that complements the both. At the same time,

frequent change in the material formulation and the

product change or discontinuation will result in the huge

cost of prequalification at the OEM end so it is also

important to make sure that the supplier with long history

and sustainable business model while assuring the

consistency in the pricing and availability of the

material.

An effective selection of plastics raw material for the

medical devices goes through the set of key property

evaluation and selection process. Most of the materials

meet very few of these properties but seldom with a unique

combination of all properties.

Polycarbonate resins and blends have excellent thermal,

mechanical and environmental properties that make them

suitable for a wide variety of medical applications.

Polycarbonate resins are an appropriate choice for medical

parts that require glass-like transparency, while

polycarbonate blends (PC/ABS) are generally opaque. It

also can be pre-coloured to achieve different colours and

special effects to meet the various applications

requirements.

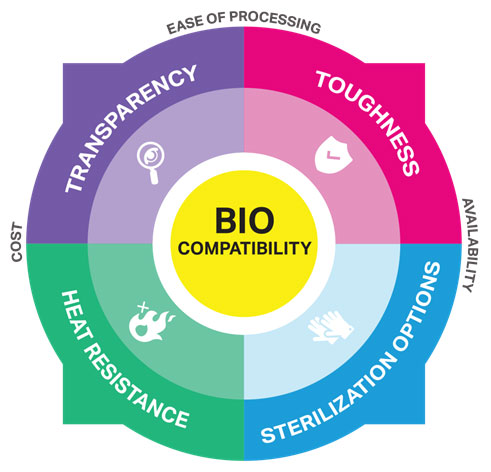

Medical devices usually encompass multiple components. It

is assembled with complex joints / assembly methods and

under goes the sterilization process before delivery.

Hence, the material used to make the components should

support the necessary combination of the properties as

detailed in the pictorial illustration. The safety of the

entire device system (in terms of biocompatibility to

human body) must be proven according to India medical

device rule 2017. The OEM’s regulatory liability is better

managed if the raw material is already assessed to be

biocompatible.

Covestro offers many polycarbonate resins

and blends that have been specially developed to meet the

requirements of medical applications, including Makrolon®

polycarbonate, Apec® high heat polycarbonate, Bayblend®

PC+ABS blends and Makroblend® PC+PBT & PC+ PET blends.

How does Polycarbonate become the

material of choice for the renal care products?

Patients who have lost kidney function and

have been diagnosed with end-stage renal disease often

require external treatment of their blood (hemodialysis)

to remove excess water and toxins.

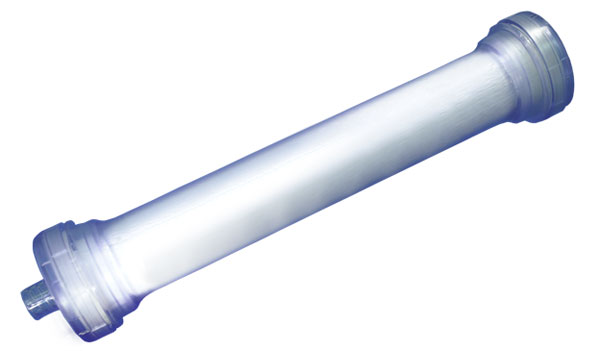

Hemodialysis is most often accomplished by

passing the patient’s blood through a semi permeable

membrane cartridge. Filter cartridges engineered from

polycarbonate provide a rigid housing that supports and

protects the fragile hemodialysis membrane.

The polycarbonate material resists

shattering during manufacture, shipping and during the

clinical use.Its thermal stability allows for single-pass

steam sterilization or processing via EtO or irradiation

(both gamma and electron-beam). In the process, clarity of

the housing is vital, enabling the dialysis technician to

observe the procedure.

Product : Hemo-dialyzer housing

Material : Makrolon® Rx2440

Advantage :

-

Biocompatible according to ISO10993-1 and

USP Class VI

-

Rigid yet tough

-

Dimensional Stability

-

Glass like transparent,

-

Steam, EtO, Gamma and eBeamsterializable

|