|

New Innovations - Expanding horizons for

Thermoplastic Elastomers in Medical Applications

|

A glimpse from Molay Das - Kuraray India on

how the new generation TPE’s finds the way to resolve several safety and

performance issues... Within the medical industry,

demand is rising for safe and halogen-free polymers used in manufacturing

medical products. Many polymer companies are feeling the need with new

materials like thermoplastic elastomers (TPEs). For several decades, the

medical industry has relied upon styrenic block copolymers (SBCs), a type of

TPE, for use in a range of medical products. TPE process easily, have

excellent mechanical properties and elasticity, and possess strong haptic.

Their inherent low toxicity and compliance to medical and food contact

regulations make TPEs a safe choice for specifying materials for use.

With more than 30 different types of TPEs with individual

product properties, Kuraray offers a diverse portfolios for the medical

market. These TPEs are safe and non-toxic and offer flexibility and

performance in the design of medical products where superior performance and

safety is needed most.

Kuraray’s TPE products, SEPTON™ and HYBRAR™ combine the

elastic properties of rubber with the benefits of thermoplastics. Due to

this thermoplastic nature, they can be processed into almost any shape.

These TPEs have a soft touch and provide comfort and durability. |

Mr. Molay Das

Manager, Market Development

Kuraray India Pvt. Ltd. |

Distinguished by their high clarity, non-allergenic characteristics, and easy

process ability, SEPTON™ and HYBRAR™ are perfect for applications such as

medical tubes and pouches, orthopedic gels, elastic nonwovens and films, patch

adhesives, and medical bags.

Medical Tubes :

As environmental standards increase, medical tubes are now being replaced with

polymers such as HYBRAR™ as a costeffective solution for soft-touch

applications. Due to its toughness, transparency, flexibility and physical

properties, HYBRAR™ meets many of the new characteristics needed for medical

tubing. This TPE has excellent miscibility with polypropylene (PP) and has high

affinity to polyolefins and styrenics making it extremely transparent and easy

to process. HYBRAR™ blends with PP are soft, transparent, offer good kink

resistance, have high-temperature performance and are solvent bondable. In

comparison to PVC, Kuraray HYBRAR™ has similar physical properties but lower

density. Being halogen and phthalate free, HYBRAR™ meets many of the

environmental and safety standards that PVC cannot meet. Moreover, compounds

made out of HYBRAR™ and PP have high tensile and excellent impact strength. The

polymer structure of HYBRAR™ also ensures relatively good oxygen and moisture

permeability compared to other elastomers.

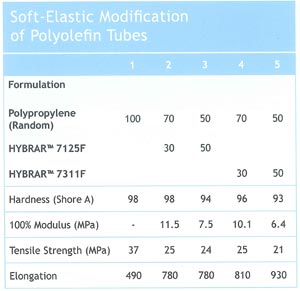

The below graph shows the range of properties possible when blending HYBRAR™

with various ratios of PP.

Orthopedic Gels :

Kuraray’s SEPTON™ is a series of high-performance, thermoplastic rubbers that

are based on Kuraray’s SEEPS technology. Styrene Ethylene Ethylene-Propylene

Styrene (SEEPS) grades are comprised of copolymers with both isoprene and

butadiene in the midblock. SEPTON™ 4,000 Series can be used to create orthopedic

gels. The SEPTON™ 4000 Series provide orthopedic gels with their necessary

stability and super soft characteristics giving the products a natural skin-like

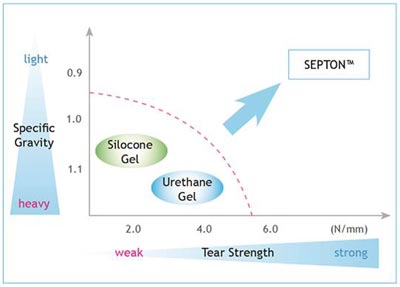

feel and performance over a broad temperature range. With their low specific

gravity and high tear strength characteristics, these products can replace

silicone in various applications. Additionally, characteristics like lower melt

viscosity, excellent low temperature behavior and superior process-ability at a

low shear rate ensure enhanced overall process-ability and production

efficiency.

Developed for high-performance products where long lasting stability and

compression set are key requirements, SEPTON™ 4000 Series can be used in

applications such as cushions for artificial limbs, orthopedic bandages,

prostheses and burn plasters. Their excellent shock absorbing and damping

properties combined with non-allergenic qualities meet the high demands in this

industry.

The below graph shows the comparison of tear strength and density of SEPTON™ to

Silicone and Urethane Gels.

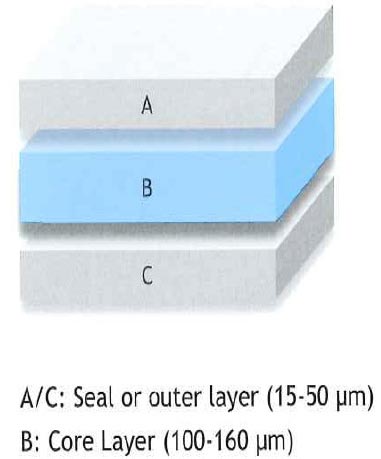

Medical Bags :

Kuraray’s SEPTON™ and HYBRAR™ lines are suitable for dry blending in film

extrusion processes, most often found in the manufacturing of medical bags. Both

TPEs show maximum softness and elasticity. Due to their excellent compatibility

with polyolefins, they allow great flexibility to create film properties that

normally cannot be achieved with commodity polyolefin resins alone. They perform

well in high temperatures, can be sterilized and can be down-gauged due to their

improved impact resistance. Furthermore, there is no migration of PVC

plasticizer as compared to PVC bags.

In the field of flexible packaging films made from polyethylene and

polypropylene, HYBRAR™ offers various grades that can be added for specific

customization. Compared to plastomers or Polyolefin elastomers, these materials

perform in the lowest concentrations necessary to achieve maximum value. The

main advantage is impact resistance for down-gauging purposes. Specifically for

polypropylene, HYBRAR™ can reduce the Sealing Initial Temperature (SIT) up to 10

degrees.

Elastic Nonwovens and Films :

As elastic nonwovens and films continue to grow their presence in the market, so

have the needs to maintain optimal cost performance balance.

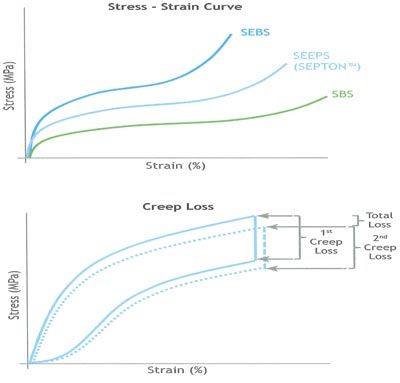

Kuraray’s SEPTON™ 4000 Series is designed for high-performing elasticity making

them an excellent solution for many elastic nonwovens and films. For consumers,

the main advantage is higher comfort and a decrease in creep resistance. These

distinct properties further lead to down-gauging probabilities. Also,

significant material savings – as much as 40 percent lower material usage and 40

percent weight reduction over competitive products – can be achieved while

maintaining mechanical properties, compared to other thermoplastic elastomers.

Kuraray’s SEPTON™ 4000 series combines the strength of SEBS with the softness

expected of SBS and SIS elastomers.

Patch Adhesives :

Various products within Kuraray’s SEPTON™ line can be processed for patch

adhesives. The SEPTON™ 4000 Series can be used when there is a need for products

with extremely high cleanliness. Their well-balanced adhesion and cohesion force

makes patch adhesives with SEPTON™ products easy to peel off. For the consumer

this means better comfort without the risk of causing allergies.

Medical applications today are becoming more demanding from both a performance

and safety standpoint. This requires materials that go beyond standard SBCs that

satisfy value added solutions in a variety processing technologies and end use

conditions. SBCs continued advancement in extrusion and injection molding

process development further drive adoption into new application areas. Due to

the concerns with Poly-Vinyl Chloride (PVC), SBCs offer a safer and more

environmentally friendly alternative with comparable performance. As the market

continues to evolve, so has technology, with new materials.

Kuraray India is focused on marketing of Kuraray special polymers to meet the

emerging requirements from Indian market in combination with technical supports

and excellent services to the customers. |