|

Medical Tubing And Extrusion Technology

Advances

& Limitations

Advances in

Medical polymeric tubing science and extrusion technology

directly correlate to the evolution from surgical-based

intervention to minimally invasive approaches and

associated medical device design. The goal of reducing

procedure and hospitalization times, and patient trauma,

while improving outcomes has created a dependency on

tubing and extrusion science to keep pace with clinical

demands.

Medical

tubing plays a major role in promoting cost efficiency

because cardiac and urinary catheterization that involves

the use of catheter tubing, greatly reduces the time taken

for the concerned medical or surgical procedure. As a

result, the hospital stay is shortened, which, in turn,

lowers the overall charges a patient is likely to pay for

treatment.

Today’s

medical device engineers must understand the advances and

limitations of tubing technology as defined by both the

extrusion process and post-extrusion technology in order

to take advantage of the best designs and ensure the

success of their products. Medical device manufacturers

are being challenged by strong market demand for tubing

that delivers increased functionality, lower profiles, and

lower costs - pushing the limits of material behavior and

manufacturing science. Next-generation balloon catheters

are expected to deliver significantly higher burst

pressures and better puncture resistance. They are also

being designed to transport target-specific drug polymer

payloads or flexible microelectronic packages to various

parts of the human body. Designs are calling for ever

smaller and more capable medical devices, and many are

made to last only one operation. Smaller tubes accommodate

the trend to less invasive procedures because less

traumatic procedures shorten patient recovery times. The

challenge is to make them tight enough for a reliable

design in terms of how the product will be used, yet loose

enough to facilitate assembly and avoid unneeded features

and costs.

Braiding

and coiling can improve performance in medical device

applications by increasing torque force or the bend radius

of a tube. Designing and developing complex multiple lumen

tubing can spur innovation, provided that the designer

understands the latest technology and how best to work

with a tubing manufacturer.

Tubes and

Catheters Sizing

Problems

can arise when the customer and catheter or tubing

supplier are not using the same scale when discussing

catheter tubing sizes.

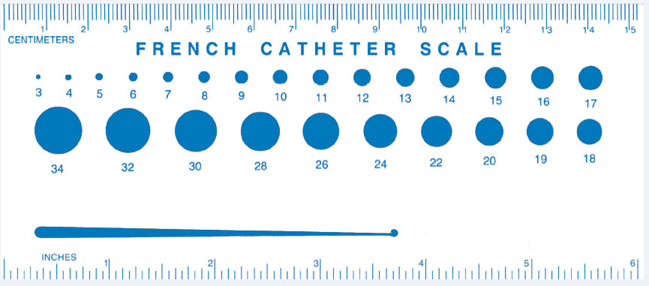

French

scale and gauge scale are the measures used to refer to

the diameter of catheters and tubing. While each have

certain advantages, misinterpreting these standards can

lead to confusion . “OD” and “ID” are abbreviations for

outer diameter and inner diameter, respectively, and are

generally measured in inches or millimeters.

The

catheter sizing classification most commonly used in the

medical industry is the French (Fr) scale, also known as

the “Charrière’s system.” The French scale is an easy

method to use to describe the basic size of a catheter,

because it specifies the most obvious component, the outer

diameter. The French size = 3 times the diameter in

millimeters. The disadvantage of the French scale is that

it does not specify the inner diameter of the catheter or

tubing. Thus, the French sizing used alone, is not

specific enough to adequately describe small catheters,

where internal diameter is critical. This scale is much

more useful to specify larger catheter sizes.

A second

method of sizing catheters is the gauge measurement. Gauge

is a descending scale, opposite the French scale of

measurement which ascends with corresponding size. The

higher the gauge size the smaller the tubing.

Another

less common method for sizing catheter tubing is the “PE”

scale. It is specific to polyethylene and is an ascending

scale used by some manufacturers to represent the OD and

ID of the tubing, similar to French sizing.

The most

definitive method to describe a catheter’s dimension is

simply to state the exact measurements of both the outer

and inner diameters. While it may seem a little more

difficult to communicate, this method will actually give

all the details necessary to the researcher or catheter

manufacturer to properly size your specific catheter and

catheter connections.

(Ref:

http://www.alnmag.com/articles/2011/08/french-gauge-odid-mm-inches-what-does-it-all-mean

https://en.wikipedia.org/wiki/French_catheter_scale)

Page

1 :

2 :

3 :

4 :

5

|