|

Medical Device Sterilisation : Key Essentials, Options And

Challenges

Importance Of Sterilisation

.

|

|

Ms.

Divya Ganapathy

Technical Consultant- Medical Device Regulatory

Services

UL India |

|

Mr.

Jan Peeters

Global Program Manager, Scientific Director & Primary

Designated Engineer (PDE)

UL Germany |

The sterilisation of medical

devices (MDs) has become increasingly complex in order to

prevent patient exposure to infections caused by organisms

on instruments and devices used during treatment.

Inadequate sterilisation of

MDs results in a significant increase of potential patient

nosocomial infections and mortality/morbidity concerns.

Beside patient health, it also increases costs for

patient, healthcare institute and system. The industrial

sterilisation techniques of MDs most often used worldwide

are steam, ethylene oxide (EO), and gamma and electron

beam irradiation. Further techniques are typically

chemical sterilisation, such as low-temperature hydrogen

peroxide gas plasma, low-temperature per acetic acid gas

plasma, vapor-phase hydrogen peroxide, ozone and chlorine

dioxide.

Sterilisation of medical

devices is of the utmost importance in the medical field.

Thousands of patients die every year or are infected

with disease because medical devices were not properly

sterilised. Complications after surgery are often the

result of an improper sterilisation. Sterilisation of

reusable medical devices is of the utmost importance to

prevent the spread of diseases. If proper sterilisation

was not practiced, a number of medical problems can occur.

As evident, these problems can be simple or complex in

nature. However, they are relatively simple to prevent.

The growth and spread of diseases are just two of the most

important reasons why medical devices must be sterilised

before use. Bacterial spores are the most resistant of all

living organisms because of their capability to withstand

destructive agents. Chemical or physical processes used to

destroy all pathogenic microorganisms, including spores on

a medical device have their specific function.

Nevertheless, if the sterilisation parameters of the

sterilisation process meet those of the validation, the

sterilised instruments, supplies and equipment are

considered to be sterile.

The disinfection of

reusable medical instruments is a frequently used

practice. There is a significant difference between

disinfection and sterilisation. Sterilisation is defined

by ISO 17664 as a “process used to render a device free

from all forms of viable microorganisms” whereas

disinfection is defined in this standard as a “process

used to reduce the number of viable microorganisms on a

product to a level previously specified as appropriate for

its further handling or use.”

Importance of Sterilization

Importance of Sterilization

Because disinfection is faster

and less expensive, some hospitals substitute high level

disinfection for sterilisation of medical instruments. An

object should be disinfected and/or sterilised depending

on its intended use. Critical reusable devices (those that

are introduced directly into the bloodstream or which

contact a normally sterile tissue or body space during

use, such as laparoscopes, intravascular endoscopes and

all endoscope biopsy accessories) require sterilisation

before use. Semi-critical and non-critical devices that

touch mucous membranes or intact and non-intact skin, like

respiratory therapy equipment, and diaphragms, require at

least a high-level disinfection. If a reusable device is

only subjected to a high-level disinfection, it may not be

labeled as “sterile.”

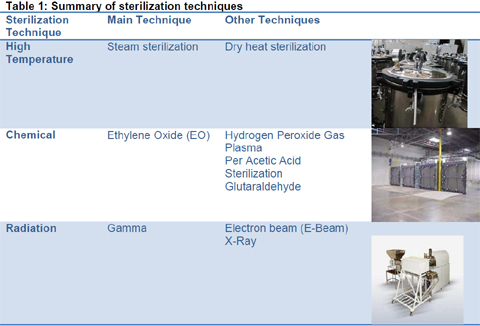

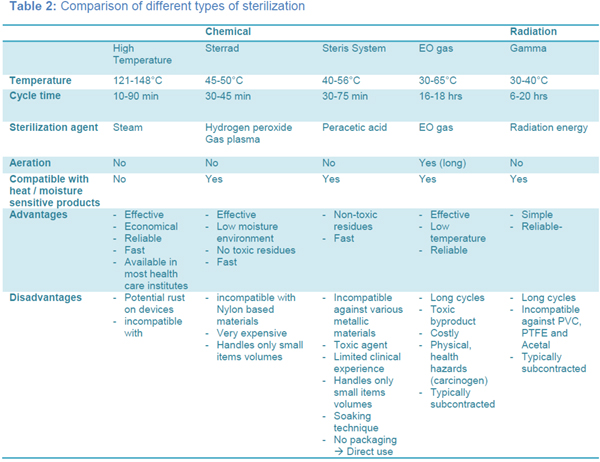

Sterilisation is

categorized into high temperature sterilisation, chemical

sterilisation and radiation sterilisation. Tables 1

and 2 summarize the various sterilisation techniques

available within each category.

Validation And Importance:

As discussed above, only

products going through validated processes are evaluated

as being sterile. Therefore, process validation is

important for the safety, reduction of variation in

results and greater confidence in the reliability of

results and is necessary in view of quality assurance of

sterilisation and disinfection, regardless of technique.

It must be performed systematically and should include all

systems, facilities and processes. The validation should

demonstrate that they perform adequately and consistently

as specified. The complete validation must be documented.

A validation confirms that the processes have been

properly developed and are under control. It demonstrates

a high degree of assurance that uniform products will be

produced over a longer period of time that always meets

the predefined specifications.

The advantage of a validation

is to receive a better understanding of processes and thus

streamline the processes. It decreases the risk of

regulatory non-compliance and requires less in-process

controls and end product testing. Validation should be

considered for all processes, especially when using new

processes and equipment is used. Re-validation should be

considered when processes and equipment have been altered

to suit changing priorities and where the product test has

a poor and unreliable indicator of quality.

Importance Of Sterilisation

Process validations are

typically completed prior to the release of the finished

product (prospective validation). In case this is not

possible, it may be necessary to validate processes during

routine production (concurrent validation). Non-validated

processes, which have been in use for some time without

any significant changes, may also be validated according

to an approved protocol (retrospective validation).

Conclusion

Medical Devices can be

sterilised using various techniques. Depending upon the

materials used as well as the availability of the

sterilisation technique, a certain sterilisation technique

should be chosen. However, first after subjecting

single-use and reusable MD to validated sterilisation

processes the products can be used as sterile products and

thus increase patient safety.

Page

1 :

2 :

3 :

4 :

5 :

6 :

7 |